Understanding the Significance of 10 Degrees Automotive in Vehicle Dynamics

The term “10 Degrees Automotive” might sound like a very specific technical detail, but it’s a critical factor in understanding vehicle handling, suspension design, and overall driving performance. This angle, or rather, the concept behind it, touches upon various aspects of automotive engineering, influencing how a car behaves on the road and how effectively its components work together. In essence, the principles associated with 10 degrees in automotive systems are fundamental to achieving stability, comfort, and optimal control. But what exactly does this 10 degrees signify, and why is it so important? Let’s delve into this intriguing aspect of automotive design.

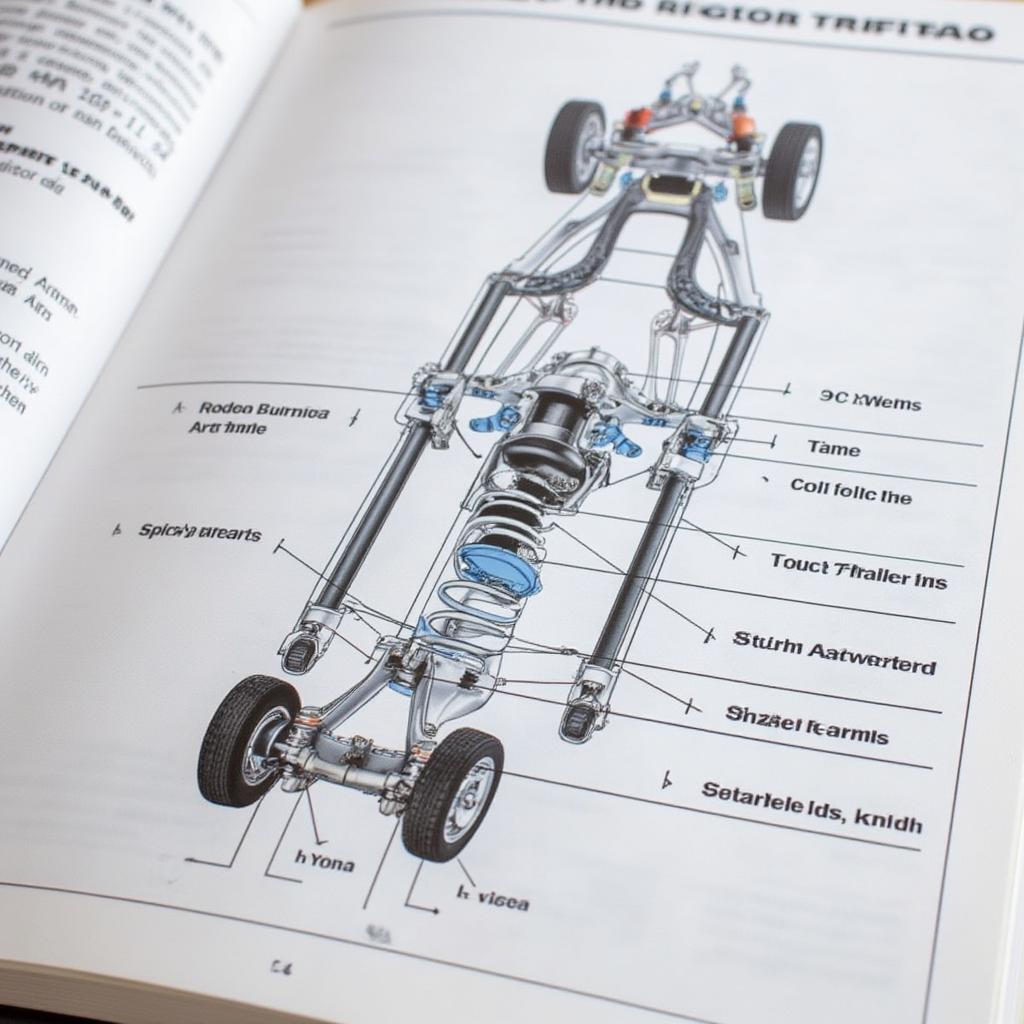

The Role of 10 Degrees in Suspension Geometry

When we talk about “10 degrees automotive,” we often refer to angles within the suspension system that contribute significantly to a vehicle’s handling characteristics. These angles, including caster, camber, and toe, are measured relative to the vehicle’s horizontal and vertical axes. The caster angle, for instance, affects the vehicle’s straight-line stability and steering feel, while the camber angle influences tire wear and cornering grip. The toe angle, whether it’s toe-in or toe-out, is responsible for directional stability and responsiveness. Adjusting these angles, within a certain degree, and perhaps close to our target of 10 degrees, is paramount to optimizing the vehicle’s performance.

- Caster: A positive caster angle, where the steering axis is tilted rearward, promotes directional stability. This is why shopping carts tend to track straight; their caster angle is very large.

- Camber: The angle of the wheel relative to the vertical axis. A small amount of negative camber can improve grip during cornering.

- Toe: The direction of the front edges of the tires in relation to each other. Slight toe-in or toe-out is critical for straight-line driving and stability.

How 10 Degrees of Adjustment Affects Handling

Often, car manufacturers will specify a 10 degrees of range for adjustability of certain angles, like the caster. If there is no specific design intention, that is the total amount of adjustment allowed for, not necessarily the specific angle the car should have at all times. A 10-degree adjustment range in a critical area like caster can have a dramatic impact on the vehicle. For instance, if the caster angle is too far from the design spec it can cause a car to wander, and on the other hand, if it’s not enough then the steering may feel too light and lack feedback. Likewise, with other suspension parameters, small deviations close to, or around the 10 degree mark are enough to change the car’s handling dramatically, highlighting why the 10 degrees measurement is important.

“The precise geometry of a vehicle’s suspension is paramount to its handling and safety. Deviations from factory specifications, even by a few degrees, can lead to undesirable consequences,” explains Dr. Anya Petrova, an automotive engineer specializing in vehicle dynamics, from the University of Zurich.

The interplay between these angles, often hovering around this 10 degrees of critical design, influences not just how the car steers but also how it absorbs bumps and maintains contact with the road. This level of control becomes crucial when the car is pushed to its limits, such as during emergency maneuvers, or on a race track. Understanding and adjusting these aspects of the suspension is a key part of maintaining a vehicle’s optimal performance. To delve deeper into automotive mechanics, exploring automotive mechanics and electronics can provide a strong foundation.

Why is 10 Degrees of Accuracy Necessary?

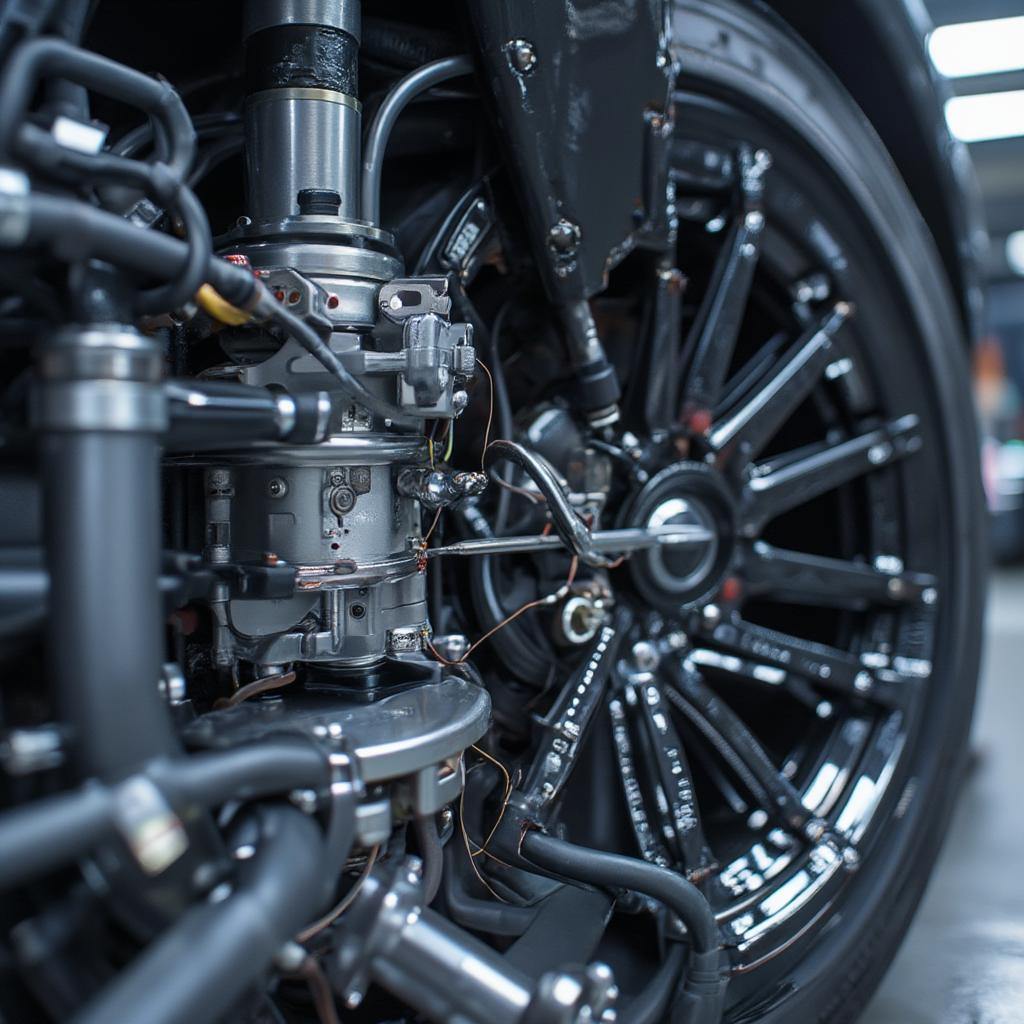

The need for precision, often expressed as 10 degrees, extends beyond the suspension system. It also applies to other aspects of vehicle engineering, such as engine components, drivetrain elements, and even the chassis itself. In automotive manufacturing, tolerances are often quite small, with deviations of just a few degrees, or in the case we are discussing, deviations from the nominal value of 10 degrees, being unacceptable. This accuracy ensures that all parts work in harmony, maximizing efficiency and minimizing the risk of premature failure.

- Engine Performance: Precise alignment of engine components, valves, and camshafts, measured down to fractions of a degree, is essential for optimal combustion and performance.

- Chassis Integrity: Even slight misalignments in chassis parts can affect the vehicle’s structural integrity and safety.

- Drivetrain Efficiency: Gear ratios and shaft alignments need to be within tight tolerances for smooth power delivery and minimal wear and tear.

This emphasis on precision, particularly around critical design parameters like 10 degrees, leads to improved performance, extended component lifespan, and most importantly, increased safety. The principles of accuracy are fundamental in automotive design, and it allows components to work better, and for longer, with fewer failures.

The Impact of Small Deviations

A seemingly small deviation from optimal specifications, let’s say something around 10 degrees, can lead to significant problems. For instance, an engine with misaligned valves can experience reduced power output, increased fuel consumption, and even catastrophic failure. Similarly, suspension angles that are too far from ideal can cause uneven tire wear, poor handling, and instability, this is why such a number is important to be within range of. This shows why there is an emphasis on accurate specifications. These issues are why precision and specific angles, including those related to our 10 degrees reference are essential and why they are so important to be within those tolerances.

To see how engineering principles are applied in the real world, consider pursuing universities with automotive programs which will provide insight into practical application.

The 10-Degree Rule in Active Safety Systems

The principles of accuracy and precision also extend to active safety systems in modern vehicles. These systems, such as Electronic Stability Control (ESC), Anti-lock Braking System (ABS), and advanced driver-assistance systems (ADAS), rely on precise sensor readings and accurate calculations to function effectively. While the 10 degrees we’re discussing here is not a specific measurement within these systems, the principle of accuracy is the same. If sensors are misaligned by even a small amount, the systems’ ability to intervene and help the driver may be compromised, leading to potential safety risks.

- Sensor Calibration: Sensors must be calibrated accurately to provide correct readings, especially in safety-critical systems.

- Algorithm Precision: Algorithms in ADAS need to be accurate to determine when the system needs to intervene.

- Component Alignment: All active safety system components must work in sync, and that requires close to perfect precision.

This level of accuracy ensures that safety systems respond appropriately in dynamic driving conditions. This is particularly important when considering high-performance driving. The accuracy of these systems can impact the effectiveness of all the support systems, including ESC, ABS, and ADAS.

“Modern vehicles are sophisticated machines that demand meticulous attention to detail. Every component, every measurement, has an impact on its overall performance and safety,” says John McGregor, a lead design engineer at a major German car manufacturer.

Why is Precision Important in Active Safety?

A lack of precision in the calibration of these systems can lead to potentially dangerous situations. For example, if an ABS system’s sensors are incorrectly calibrated, the braking distance might be significantly compromised, or the emergency braking function could come on at the wrong time, with the wrong force, or not at all. The same can be said for ESC, as it relies on accurate sensor readings to prevent skidding. Ensuring precision at every stage, including measurements and calibrations, is critical in guaranteeing these active safety systems function flawlessly and keep drivers and passengers safe. If you would like to learn more about becoming a mechanic or car technician, then consider looking into automotive mechanic education.

The Future of 10 Degrees in Automotive Technology

As automotive technology continues to evolve, the concept of precision, while not always specifically 10 degrees, remains central to future innovations. With the advent of electric vehicles, autonomous driving, and connected cars, the need for even greater accuracy and reliability is essential. The use of advanced materials, lightweight components, and sophisticated software, all require close tolerances to ensure optimum performance.

- Electric Vehicle Efficiency: Precise alignment of electric motors and drivetrain components is crucial for energy efficiency.

- Autonomous Driving Systems: Autonomous driving heavily relies on very accurate sensor data to safely navigate traffic.

- Connected Car Technologies: Connected car systems require precise communication between vehicle components.

These trends highlight the ongoing importance of accuracy in all aspects of automotive engineering. It is a fundamental principle of automotive design, and that will not change going forward.

How 10 Degrees Helps with Precision

While the exact measure of 10 degrees may not be always involved, it is a principle that guides many of the design and manufacturing decisions for all of the systems, sub-systems and individual components discussed in the article. As technology advances, the importance of high precision in the manufacturing and engineering of these components grows, ensuring the vehicles of the future are safe, efficient and perform to the very highest levels.

“The future of automotive engineering lies in precision, not just in design but also in the way we manufacture and maintain our vehicles. As systems become more complex, our understanding and control over precision will be critical,” remarks Professor Samuel Dubois, a professor specializing in automotive systems.

In conclusion, the concept of “10 degrees automotive,” or rather, the principles of accuracy and precision that it represents, is a fundamental aspect of automotive engineering. It is integral to the function of key aspects of a vehicle such as the suspension, drivetrain, safety systems and general performance of the car. This emphasis on precision extends beyond vehicle mechanics, it also impacts safety and the overall driving experience. As technology advances, and cars become more technologically sophisticated, the need for greater accuracy and reliability will continue to grow. Understanding and respecting the principles represented by the concept of “10 degrees automotive” is key to achieving optimal performance, safety, and comfort in any vehicle. If you are interested in learning more about this complex and fascinating topic, then exploring mechanic associates degree may be the next step.

FAQ: Understanding the Concept of “10 Degrees Automotive”

- What does “10 degrees automotive” generally refer to?

“10 degrees automotive” typically refers to a range or tolerance in vehicle design and engineering, representing the level of accuracy needed for optimal performance. It’s a way to understand the importance of precision in angles, measurements, and alignments. - How does the 10-degree principle relate to suspension systems?

In suspension, angles like caster, camber, and toe are often adjusted with specific tolerances, and many times a total adjustability range around 10 degrees. These angles affect vehicle handling and stability, and small deviations can lead to poor performance or component failure. - Why is accuracy important in automotive engineering?

Accuracy is crucial for ensuring all components work harmoniously, maximizing efficiency, and minimizing the risk of failure. Even small misalignments can lead to significant performance issues and safety risks. - Can deviations from the 10-degree spec cause any problems?

Yes, deviations can cause problems, especially in areas like suspension alignment or engine component positioning, where even small inaccuracies can affect handling, engine performance, and overall safety. - How is “10 degrees automotive” related to safety systems?

While not always a literal 10 degree measurement, the need for accuracy, within a certain tolerance, applies to safety systems like ABS, ESC, and ADAS, which rely on precise sensor readings to function effectively and keep vehicles safe. - Is the 10-degree angle a specific setting in all cars?

The exact 10-degree angle isn’t a specific setting in all vehicles. It represents a precision benchmark or range, especially in adjustability where there may be 10 degrees of possible adjustment, emphasizing the importance of keeping all the vehicle’s components within certain tolerances. - How does the concept of 10 degrees apply to modern vehicle technologies?

Modern vehicle technologies, such as EVs and autonomous systems, require greater accuracy and reliability. This is especially relevant in the alignment of drivetrain components, sensor calibration and all other precision-oriented sub-systems. - What role does the concept of “10 degrees” have in the future of vehicle design?

As vehicles become more complex, maintaining close tolerances will remain a core principle of automotive engineering and future advancements, such as electric drivetrains and new safety systems.